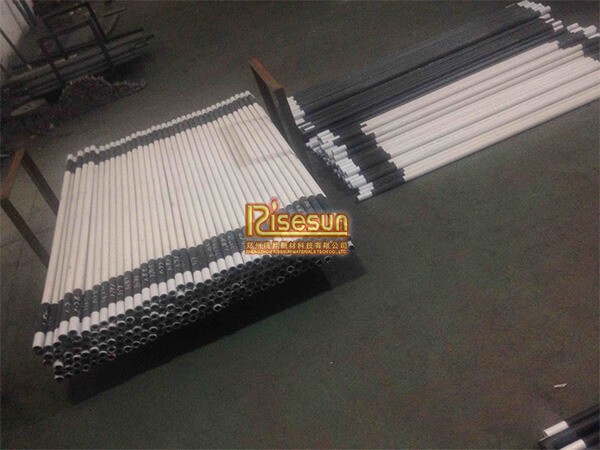

Risesun Hotbar HD - High Density SiC heating elements

Along with the development of new materials, SiC heating elements is more and more widely used, meanwhile, the working conditions of SiC heating elements are getting worse and worse in some fields.

info@risesun.co

Introduction

Along with the development of new materials, SiC heating elements is more and more widely used, meanwhile, the working conditions of SiC heating elements are getting worse and worse in some fields, such as sintering of NCM811 and NCA, higher corrosions from furnace atmosphere, which press manufacturers of refractories, kiln furniture, elements to improve performance of the products continuously in order to match demands of the market. For that, recently we developed high density (HD type) SiC heating elements successfully, which has advantages of higher density, lower porosity, higher rupture strength, anti-corrosion and longer service life. By lab test and clients’ trial run, the service life of our high density SiC heating elements improved more than 50% under various working conditions, the comparisons including in 1530℃ intermittent furnace, 1400℃ continuous furnace, furnace with strong alkali atmosphere, etc. For example, after heating in lab furnace with clear air continuously 4200 hours and surface loading 3.5W/ CM2, resistance of common elements increased about 62%, average increasing 14.7% per 1000 hours; but for high density elements, which only increased about 32%, average increasing 7.7% per 1000 hours.

|

Item |

unit |

Type |

|

|

|

|

DH & DL |

HD |

|

Density |

g/cm3 |

2.5 |

2.65 |

|

Porosity |

% |

23 |

18 |

|

Rupture strength |

MPa (25℃) |

50 |

60 |

|

Thermal Conductivity |

W/m·℃ (1000℃) |

14~19 |

14~19 |

|

Specific heat |

kj/kg·℃ (25~1300℃) |

1.0 |

1.0 |

|

Coefficient of thermal expansion |

(1000℃) × 10-6 |

4.5 |

4.5 |

Furthermore, HD type elements has more smooth resistance-temperature curve, assuming 1.0Ω resistance value of elements at 1000℃, the variation of temperature-resistances of common and HD type elements as below table:

|

Temperature |

25 |

200 |

400 |

600 |

700 |

800 |

900 |

|

Common |

1.5~4.0 |

2.20 |

1.50 |

0.80 |

0.84 |

0.89 |

0.93 |

|

HD type |

1.3~2.0 |

1.80 |

1.30 |

0.81 |

0.85 |

0.90 |

0.94 |

|

Temperature |

1000 |

1100 |

1200 |

1300 |

1400 |

1500 |

|

|

Common |

1.00 |

1.06 |

1.14 |

1.23 |

1.32 |

1.40 |

|

|

HD type |

1.00 |

1.06 |

1.12 |

1.17 |

1.19 |

1.22 |

|

Seeing from above table, firstly, the resistance consistency of HD type elements is better under lower temperature, as a result, furnace will get better temperature consistency under lower temperature; secondly, under high temperature, the resistance variation of HD type elements is smaller, especially more apparent while temperature higher than 1200℃, which will provide with longer service life of elements under high temperature

Furthermore, due to the characters of the raw materials of HD type elements and also improvement of density, HD type elements can be produced with much lower resistance value compared to the common ones. For example, 30mm elements with 1000mm hot zone, the min. resistance value of common elements can be produced is about 1.2 ohms, but for HD type elements, 0.9 ohm is available even more lower, which provides with more options for design of electrical system of Kiln & furnace, such as more heating elements in series connection. Of course, we can also produce HD type elements with much higher resistance value compared to common elements, satisfy the needs of customers.

May you like

-

Risesun Hotbar HD - High Density SiC heating elements

Along with the development of new materials, SiC heating ele...

-

Coating SiC heating elements

SiC heater can be used in the furnaces with different atmosp...

-

Alkali-resistant Coating SiC heater

mainly used in atmosphere of alkali metal, under this atmosp...

-

DH type SiC heating elements

All the rated loading and testing voltage shown in the list ...

Inquiry

If you have any questions about the company's legal policies, copyright information, trademark information, other legal topics or general questions related to products and services, we would like to hear from you. Start by filling in the form below. We will contact you as soon as possible.

简体中文

简体中文